Main content start

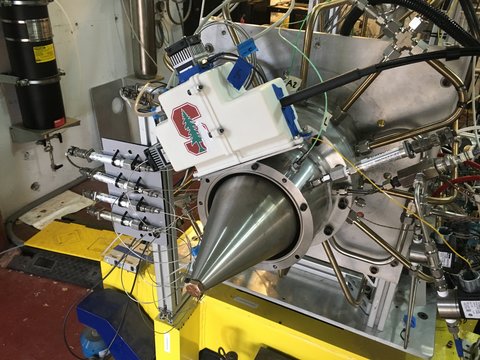

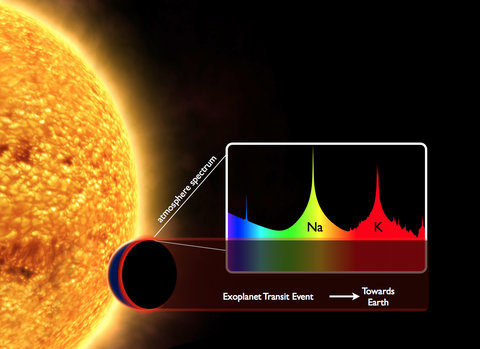

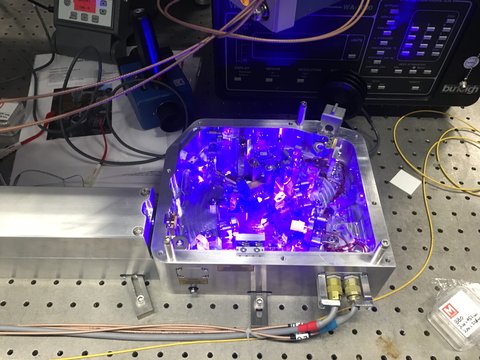

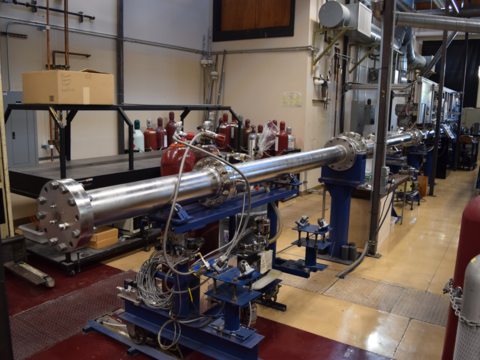

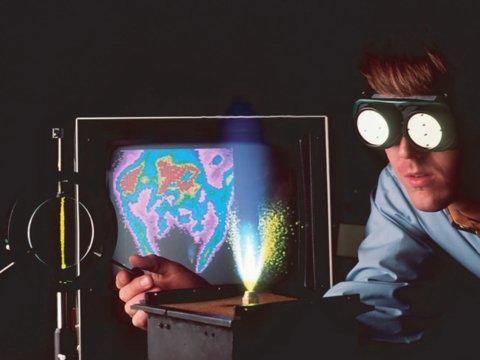

In the Hanson Research Group we investigate the fundamental science underpinning the energy and propulsion technologies of tomorrow.

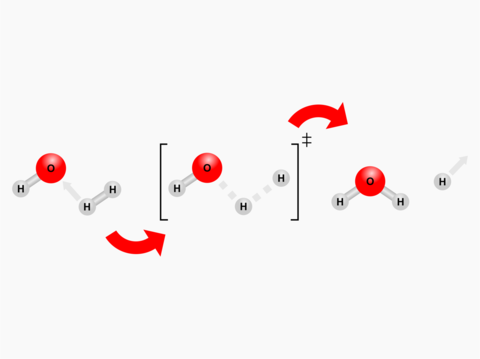

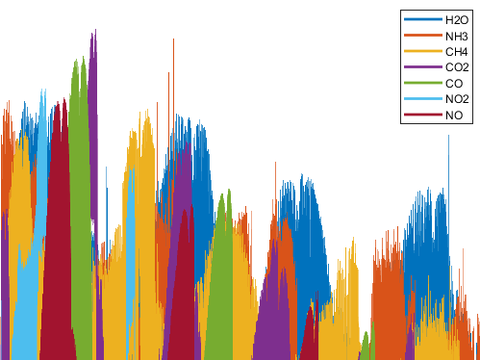

We develop leading edge diagnostics and experimental techniques to better understand and address a diversity of real-world challenges. Over the past 40 years, our group has published more than 1300 scientific papers and our more than 115 PhD graduates have made immense contributions to the fields of chemical kinetics, spectroscopy, gas dynamics, and energy science.